Zinc anti corrosive anode was designed specifically for cathode protection of reinforcing bars in concrete. It is a zinc film made of high purity zinc (more than 99.95%), coated with ion conductive adhesive. It is applied directly on the outer layer of concrete.

The zinc layer is electrically coupled with steel reinforcement. This way the electrical circuit gets closed when current flows through the layer of adhesive and concrete thanks to ion conductivity.

The simplest cathodic protection system ever.

High conductivity of zinc film ensures homogeneous distribution of cathode protection current and simplifies any local requirements regarding current distribution.

Standards:

European standard EN 12696: “Cathodic protection of steel in concrete”

NACE standard RP 0290:2000: “Impressed current cathodic protection of reinforcing steel in atmospherically exposed concrete structures”

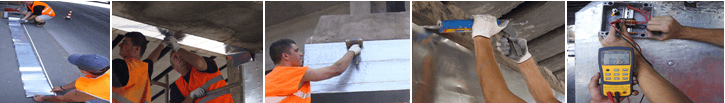

Zinc anti corrosive anode film can be cut into desired widths and manually applied to the normally prepared concrete surface. Old concrete surfaces have to be structurally sound and any damaged areas have to be repaired before applying Zinc anti corrosive anode. Residue and other types of contamination of the surface also has to be removed.

Holes, cracks and other surface defects have to be cleaned and filled using an approved method, by means of cement-based mineral plaster. The repair surface should be smooth.

When applying the Zinc anti corrosive anode film, the first step is removing the topliner protecting the adhesive. On larger areas, the topliner should be removed slowly while pressing the Zinc anti corrosive anode film to the surface. It is recommended to test application by moving and pressing a rubber mallet across the Zinc anti corrosive anode – covered surface.

KEY BENEFITS OF ZINC ANTI CORROSIVE ANODE

It effectively eliminates corrosion acting as galvanic anode.

It can be applied to the top, sides and bottom of the concrete structures of different shapes and sizes.

Quick and easy application.

It requires only minimal maintenance throughout its long lifespan.

APPLICATIONS

RESIDENTIAL BUILDINGS

INFRASTRUCTURE

DURABILITY

Zinc anti corrosive anode film is supplied in rolls (250 mm wide and 25 meters long). After applying anti corrosive film the surface should be finished with authorized, cement-based coating of desired texture and color ensuring that the edges and joints are adequately protected from moisture.

Applying the system may be done in accordance with ISO 12696.

PRODUCT FILES